Tube Mill Line

-

Boleng bo phahameng ba 32mm Stainless Steel Tube Mill line

Mohala oa leloala la tšepe e sa hloekang, eo ho thoeng ke phala e cheselitsoeng, ke phala ea tšepe e entsoeng ka tšepe e sebelisoang hangata kapa e entsoeng ka tšepe ka mor'a ho qhekella le ho etsoa ke yuniti le hlobo.Ts'ebetso ea tlhahiso ea phala ea tšepe e entsoeng ka tšepe e bonolo, katleho ea tlhahiso e phahame, ho na le mefuta e mengata le litlhaloso, 'me matsete a thepa a nyenyane, empa matla a kakaretso a tlase ho feta a phala ea tšepe e se nang moeli.

-

Mohala oa maqhubu a maholo

HIgh frequency straight seam welded pipe line e sebelisoa haholo ho hlahisa liphaephe tsa tšepe tse cheselitsoeng ka φ60.~φ219mm le botenya ba lebota la 2.0~6.0mm, hape e ka hlahisa liphaephe tse lisekoere le tse khutlonnetsepa le liphaephe tse nang le sebōpeho se khethehileng tse sa feteng mefuta e mengata ea liphaephe tse chitja.Li-tubes tsa API 5L li ka hlahisoa hamoraoka ho eketsa lisebelisoa tse hlokahalang.Mohala oa tlhahiso o entsoe le ho etsoa motheong oa ho cheka le ho monya thepa e tšoanang lapeng le kantle ho naha, ho kopanngoa le maemo a naha ea heso, ho qapa ka sebete, le ho mamela maikutlo a basebelisi ka mokhoa o pharalletseng.Thepa ke ea moruo, e ka tšeptjoa ebile e tsitsitse.

-

Boleng bo phahameng ba ERW Tube Mill line

Mohala o phahameng oa maqhubu o otlolohileng oa seam welded pipe line e sebelisoa haholo ho hlahisa liphaephe tsa tšepe tse cheselitsoeng ka φ60.~φ219mm le botenya ba lebota la 2.0~6.0mm, hape e ka hlahisa liphaephe tse lisekoere le tse khutlonnetsepa le liphaephe tse nang le sebōpeho se khethehileng tse sa feteng mefuta e mengata ea liphaephe tse chitja.Li-tubes tsa API 5L li ka hlahisoa hamoraoka ho eketsa lisebelisoa tse hlokahalang.Thepa ke ea moruo, e ka tšeptjoa ebile e tsitsitse

-

Mohala oa Tlhahiso e Phahameng ea Precision Tube Mill

Ho sebetsana le lintho le litlhoko

Morero:Thepa e sebelisoa haholo-holo bakeng sa ho bentša bokantle bo ka ntle ba tšepe e sa hloekang

Litlhoko tsa sebaka sa mosebetsi:

1. Sebaka sa bophara ba mosebetsi: 19-76mm2.Bolelele ba mosebetsi: 6000mm

3.Bokhopo ba ho qetela: Ra 0.1 (Ka ho ferekana ha holim'a metsi hangata)

4.Litlhoko tsa ho qetela tsa ho qetela: Ho sila le ho bentša

SEBELISA SEBOPEHO TSA SEHLOOHO LE LITHO

Sesebelisoa se na le sete e le 'ngoe e nang le sete e le' ngoe ea hlooho, sete ea Prenationary, sethala sa motlakase, sete ea ts'ebetso ea ho fepa, sete ea phetisetso

ho amohela (ho lokolla) mochine, sete sa tsamaiso ea ho tlosa lerōle (ho ikhethela).

1.Hlooho e sila:

Mochini o na le sete e le 'ngoe ea lihlooho tsa ho sila tse ka sebelisoang ho bentša bokantle bo ka ntle ba mosebetsi .Ho ea ka ho sila

litšobotsi tsa workpiece, sebelisa mabanta abrasive e le lintho tse sila.Hlooho e silang e na le enjene e le 'ngoe ea hlooho e bentšang, mochini o tšehetsang, mochini o tsamaisang motlakase, le poleiti e ntseng e hola.

2.Sistimi ea potoloho ea lipolanete:

Mosebetsi o ka sehloohong oa mochine ona ke ho fana ka ts'ebetso e hlokahalang ea ho potoloha ha hlooho ea ho sila nakong ea polishing.Matla a motlakase ke

e fetisetsoa ho turnable ka V-belt ho khanna ka ho toba turntable ho potoloha.E na le mochine o motlakase, o fetohang le mochine oa ho fetisa.

3.Taolo ea motlakase:

Karolo ea sistimi ke ho kenya litaelo, taolo ea motsamao oa mochini ho fihlela taolo, haholo-holo ka console le elektroniki

khabinete ea taolo, inverter le likarolo tse fapaneng tsa motlakase o tlase.

4. Sistimi ea ho fepa:

Sistimi ea ho fepa e sebelisoa bakeng sa ho fepa ka mokhoa o iketsang oa polishing ea tube e otlolohileng. E na le roller, feeder, backlash adjusting screw le motor drive.

tsamaiso.

5.Mochine oa ho amohela (ho lokolla) oa mosebetsi:

Sena ke sa ho tšehetsa li-workpieces nakong ea polishing ea tube e otlolohileng. E na le sekoti se lokisang, mabili a rabara le pallet.

6.

Mosebetsi oa tsamaiso ena ke ho bokella lerōle le hlahisoang nakong ea ho sila, ho rarolla pokello ea lerōle, ho boloka bonolo

le ho hloekisa.Haholo-holo e entsoe ka mochini o bokellang lerole la leholiotsoana, mochini o hloekisang mekotla, le lipeipi tse bokellang lerole..

Lintlha tse ka sehloohong tsa ts'ebetso ea tekheniki ea mochini:No Morero Li-le tse nang le litlolo tsa likhoho 1 Bophara bo bentšitsoeng hantle(mm) 19-76mmm 2 Bolelele bo nang le botlolo tse bonolo (limilimithara) 6000 3 Ra 0.1(Ka ho ferekana ha holim'a metsi hangata) 4 Khalefo e ntlafatsang Kopana le maemo a naha (boikhethelo) .Litlhoko tsa tikoloho ea mosebetsi:

-

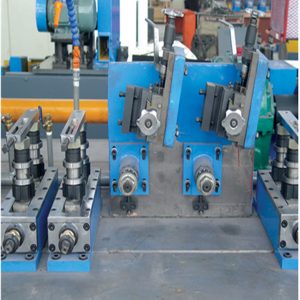

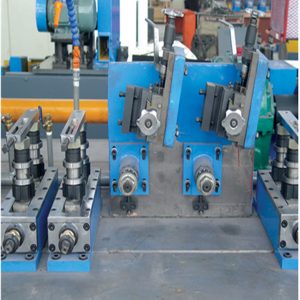

76mm Tube Mill Line Pipe Mill Line

High frequency welding e sebelisoa ha ho etsoa lipeipi tse cheselitsoeng ka tšepe.High frequency welding e na le phepelo e kholoanyane ea matla, 'me lebelo le phahameng la welding le ka fihlelleha bakeng sa liphaephe tsa tšepe tse nang le thepa e fapaneng, caliber le botenya ba lebota.

-

Tube le Pipe Mills High Frequency Welding Production Line

Mohala oa leloala la tube haholo-holo o na le sete e le 'ngoe ea hlooho ea ho sila, sete ea tsamaiso ea lipolanete, sete ea taolo ea motlakase, sete sa sistimi ea ho fepa, sete sa mochini o amohelang (ho lokolla), sete sa sistimi ea ho tlosa lerōle (ho ikhethela) .

-

Seam Steel Welded Steel Tube Mill Line

Mohala oa ho sila oa li-tube ke ho otloloha ha seam ho lisebelisoa tsa ho tjheseletsa ho tloha liphaepheng tsa tšepe tse entsoeng ka lishiti kapa li-coil tse chesang tse chesang kapa tse batang.